Our Location

No.2 Zhongxing Road, Chenchong Industry Zone, Longjiang Town, Shunde District, Foshan City, Guangdong P.R China.

HPL, full name as high-pressure laminate, also called solid laminate, compact laminate, is a game changing material for various usage in outdoor construction, kitchen countertop, cabinet, partition, the excellent strength on weather resist and hygiene safe meets the requirements of high-quality table top for heavy traffic public venues.

Core of HPL is very clean and friendly, several layers of kraft paper with phenolic resin under high pressure, surface is decorative paper can print designs and make different effects. Capable for indoor humid space and outdoor, some inferior production would use urea-formaldehyde resin to largely reduce cost, however the product is skeptical to tolerate environments.

Many enquiries ask for outdoor tabletops but received a 25mm quotation of HPL from web. HPL is multi-layer composites under extreme high pressure, making high density up to 1400kg/cbm, for example, regular finished product of a 70*70cm 12mm HPL table top weigh 0.7*0.7*0.012*1400=8kg, make to 25mm weight to 17kg. Laminate doesn’t require so strict condition, it’s much lightweight and often come in 25mm thickness, also require edge banding to seal the wood chip core. Fireproof panel is a layer of 0.8mm thick HPL veneer on laminate, many suppliers also make slim thickness and use black band to sell as HPL.

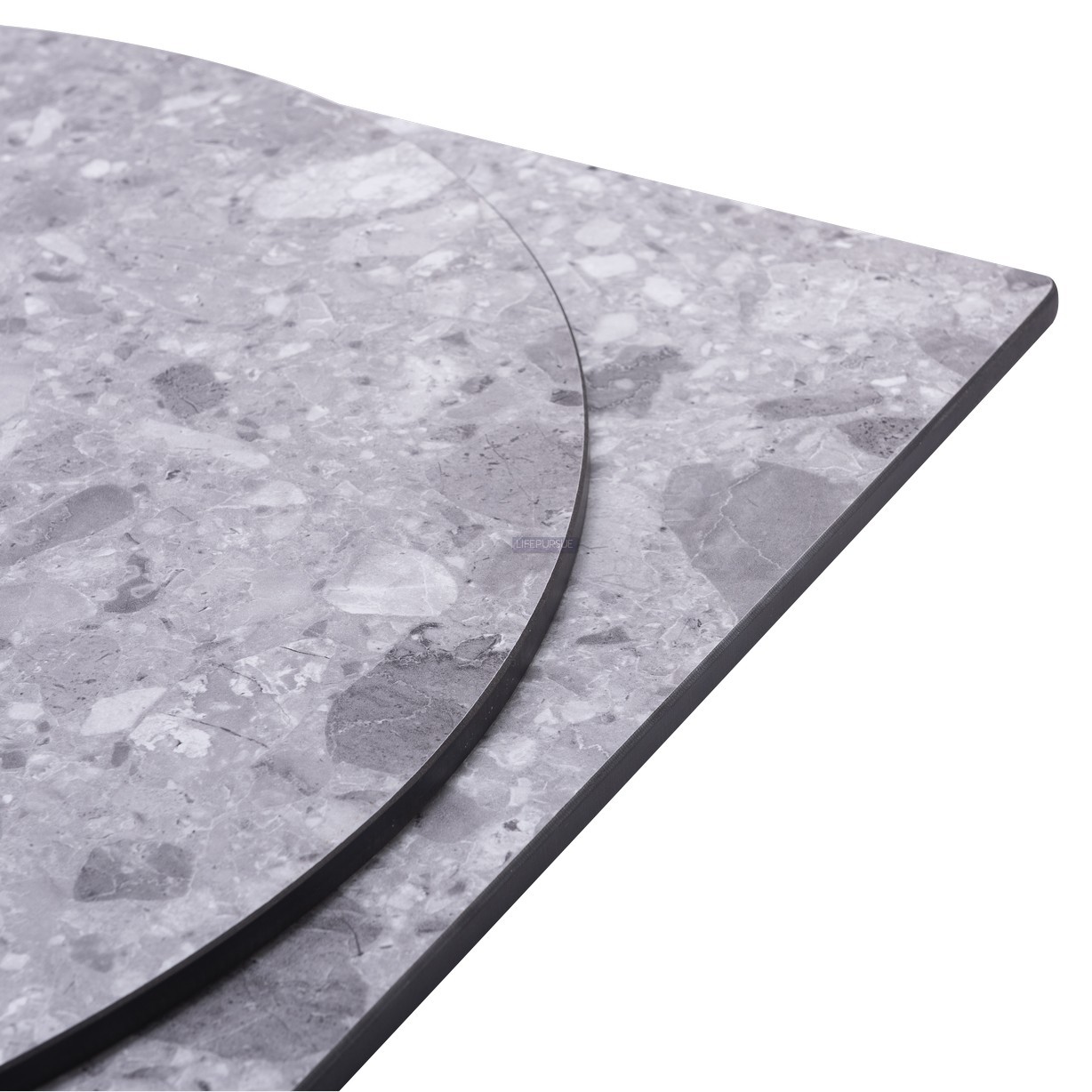

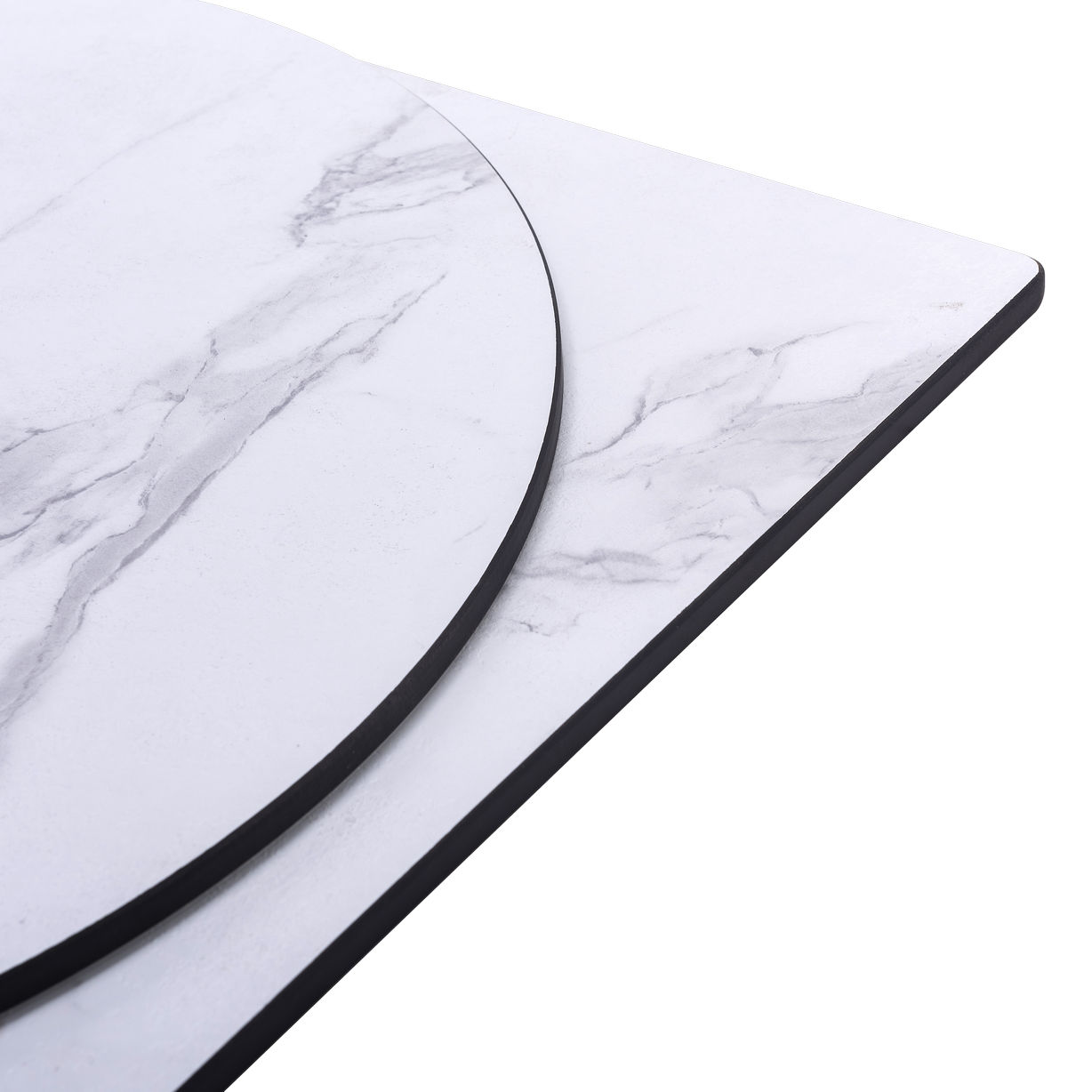

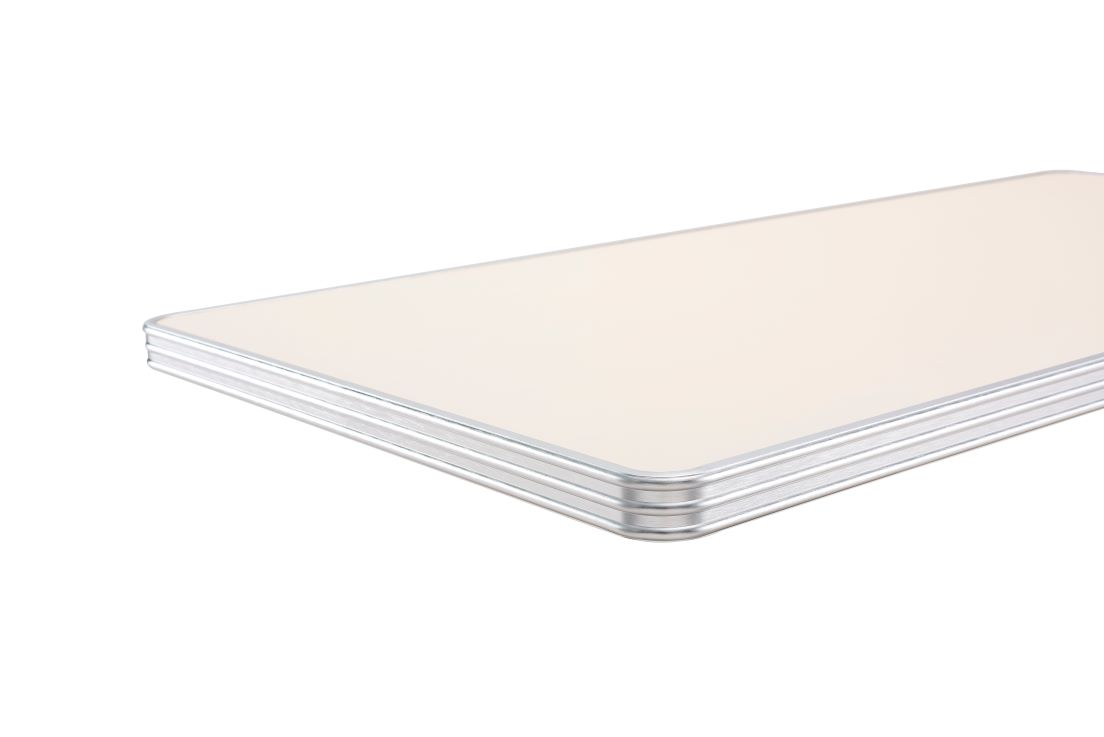

panel to table top firstly is to split the large panel to set size, most regular panel 1220*2440mm can do all type of decorative schemes, and is the first choice for less quantity needs. After cutting to pieces, the edge and corner are straight, too sharp that is dangerous to use. The next step will take hand polish to process the edge and corner. Regularly the edge is beveled (also known as Arris) that save work at the same time leave smooth feel. Corner process R10mm or custom angles.

The most difficult part for a rock-like plate is how to attach with table base. HPL has a hard surface that never use self-taping screws, it won’t penetrate and surface will chipping. Might you be think of glass or ceramic to use glue or rubber, it’s a way just beyond professional. If you have the top plate drawing of the table base, best is process pilot hole, inserted metal nuts will be useful for quick assemble, also look seamless and lasts long.

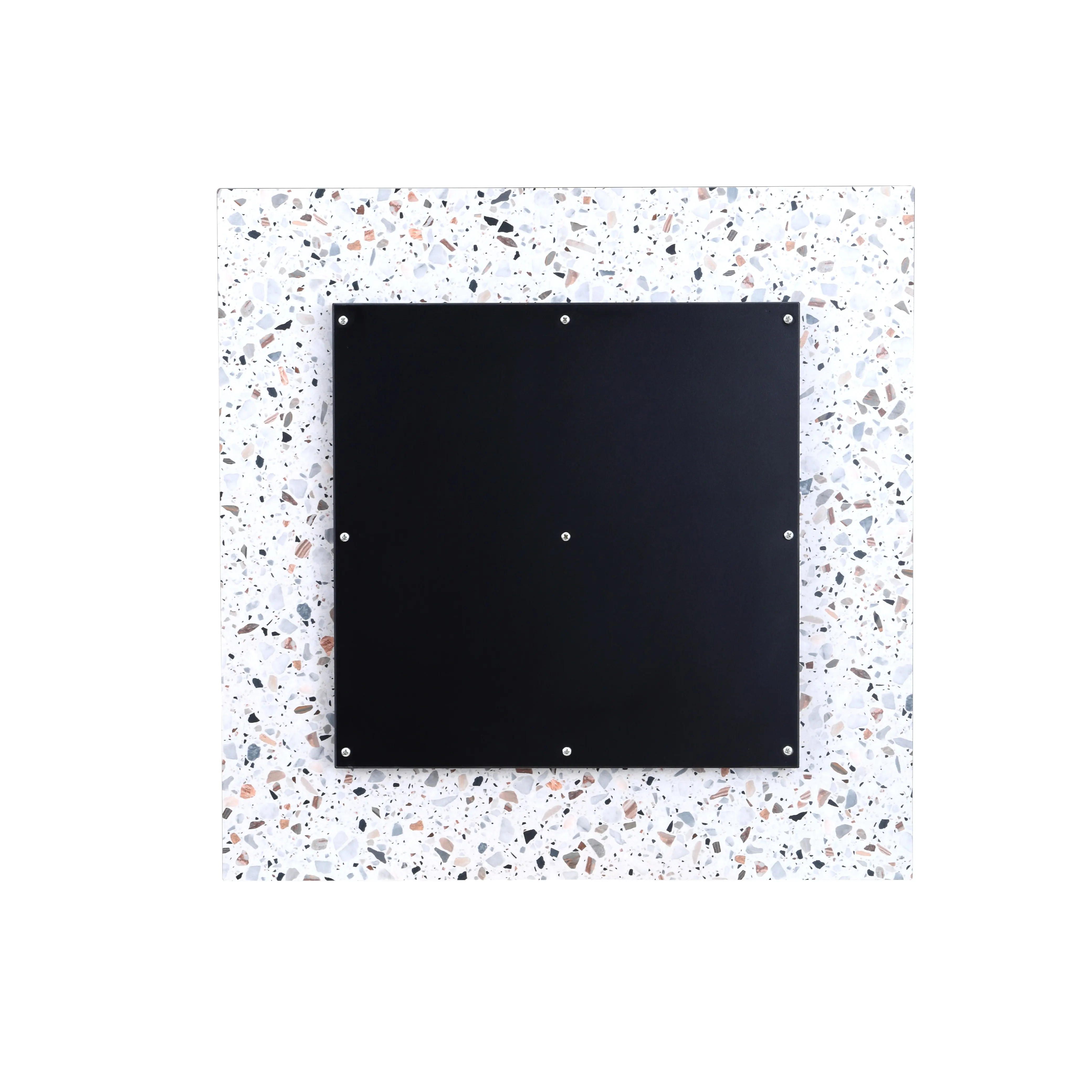

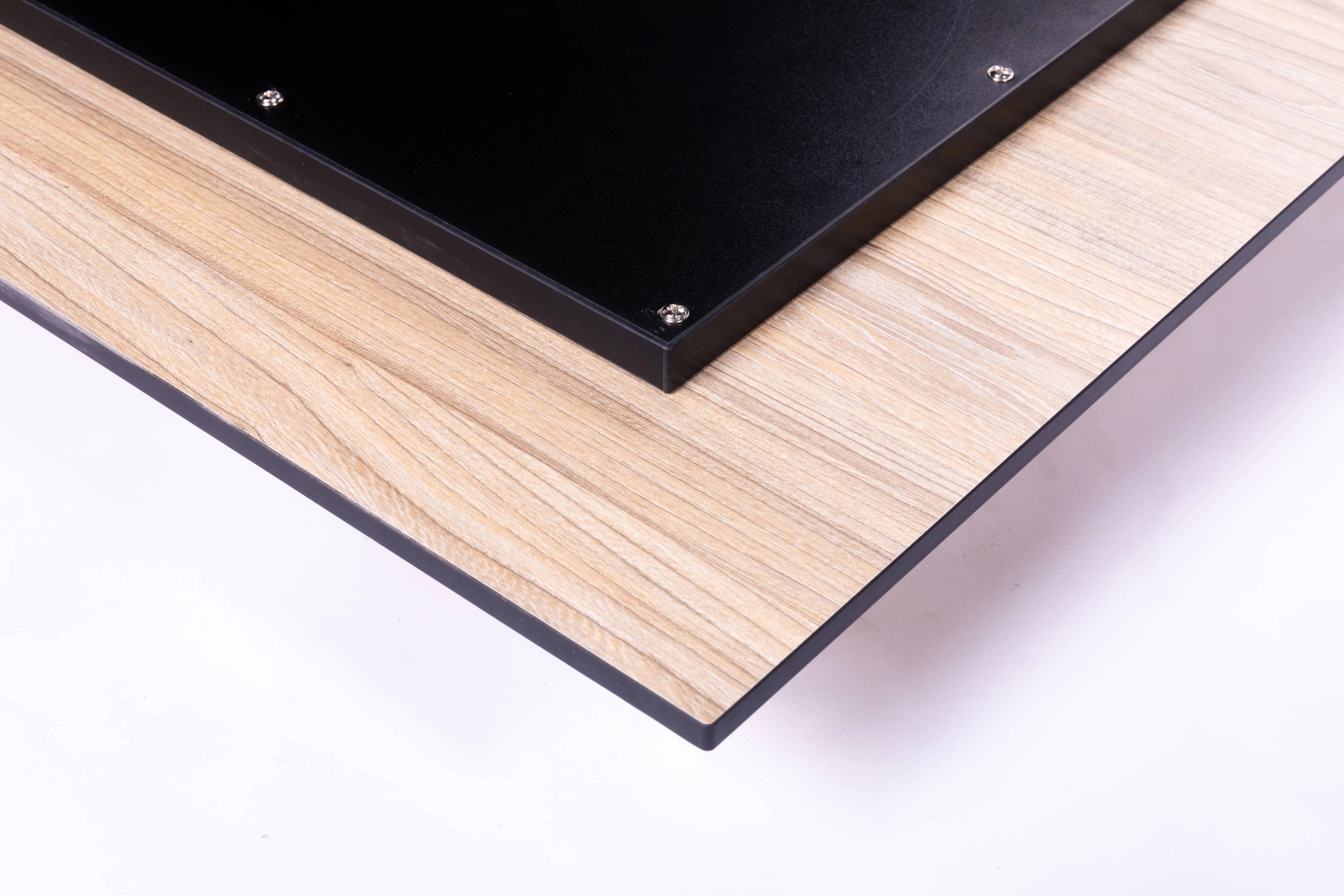

If you don’t have drawings from table base, or table top will sell separate, stick a half-sized plywood or MDF is commonly used before smart milling. Cost is adding much than the other ways, but flexible to be able to use for various spec of table bases.

To match for most top plates, in the backside process 4 milling grooves. With precise parameter, each tunnel allow screws pass but kept its head inside. The expense doesn’t adding too much, and can do per custom drawings.

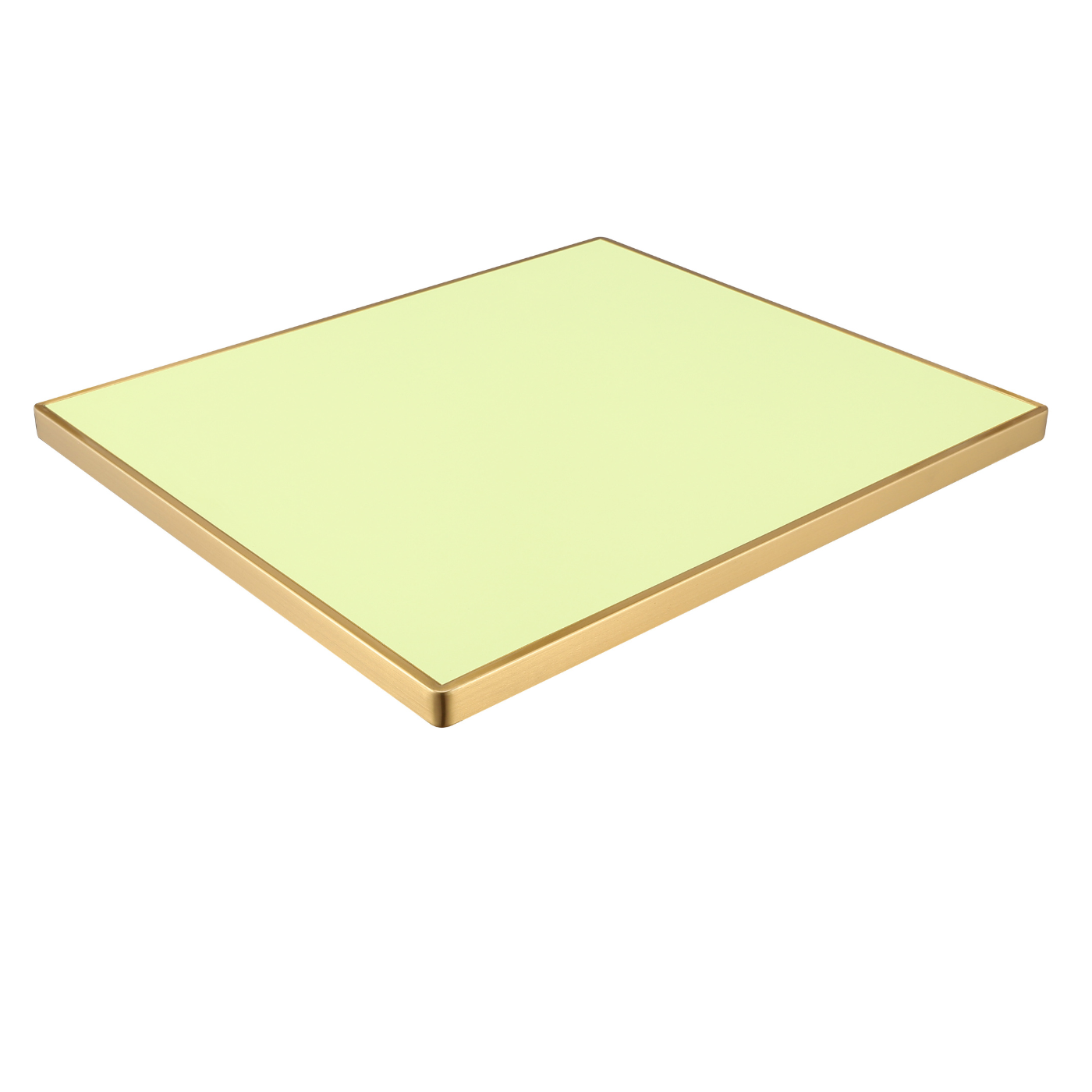

Metal edge is useful to cover the black core and protect the edge and corners, adding sophistication and elegant feel. To fully outdoor use, the substrate is marine plywood with varnish paint, edge is stainless steel 304 or anodized aluminum, costs adding a lot, nearly 3 times even more, materials, moldings, handworks are rocketing. However final product is best condition both on durability and aesthetic appealing.

The material industry is innovating time by time, offer a wide world of choices. Professional on tabletop is to help customers make furniture that don’t look old and all same, in order to serve distinguish clients with satisfied mood.